Contact: Liang Sheng

Tel: +86 (0769) 8287 2593

Mobile: +86 13712941678

Fax: +86 (0769) 8133 4403

E-mail: sanyi@dgsanyi.cn

Address: No. 2, Quanhe Street, Quantang Management District, Liaobu Town, Dongguan, China

Website: www.dgsanyi.cn

From the point of view of the current transportation industry, the three-in-one feeder is the most widely used type of feeder. It is suitable for the transportation and stamping of various steel plates, iron plates and aluminum plates. Whether it is as a conveying device or as some equipment around the press, the feeder also occupies a very important position in the stamping industry. The following three easy intelligent small series to specifically introduce the structure of the next triple feeder!

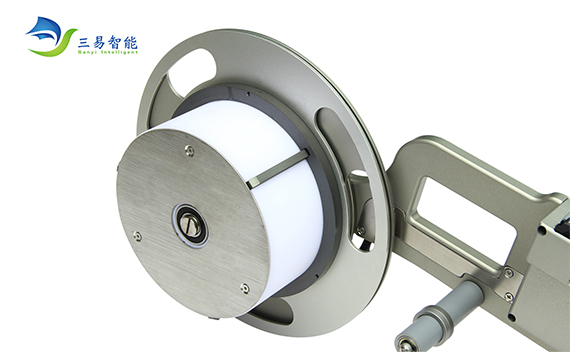

The three-in-one feeder consists of an oil-feeding trolley, a roll-opening material rack, a material feeding device, a leveling material feeding device, and a discharge port feeding rack. The loading trolley is located in front of the unwinding material rack, the revolver is located at the bottom of the trolley, and the uncoiled material rack is composed of a frame, an inflation and contraction device, a pneumatic pressing arm, and a material blocking arm (two front and rear, and the interval is arranged on the shelf machine). And the feeding arm is composed of; the feeding guiding device is located between the unwinding material rack and the leveling feeding device, and is fixed at the front end of the leveling feeding machine; the leveling feeding head is composed of an entrance width adjusting device, a leveling feeding roller and a transmission device. , Servo motor control system (composed of Mitsubishi PLC, Yaskawa servo motor, Mitsubishi touch screen), inlet and outlet adjustment handwheels, discharge wheel pressure adjustment knobs, pressure gauges, independent electronic control operating platform; discharge mouth rack Located at the discharge port of the leveling feeder head, it consists of a multi-plated hard chromium plated roller to ensure the reliable transfer of the material band after the length is reached.

When the three-in-one feeder is used, the material roll is placed on the V-type bracket of the loading cart and the bogie is moved so that the center of the material roll coincides with the center of the material frame of the three-in-one feeder as far as possible. Start the material frame, and the material roll enters the tensioning and shrinking barrel to be tensioned. At the same time, the width of the blocking arm is adjusted according to the width of the material roll so as to precisely limit the material roll. Then open the three-in-one feeder independent operation panel, enter the manual operation screen and click on the press arm to lower, the press arm cylinder starts to work, and push the press arm to the direction of the roll, so that the press arm presses the material.

The feed roll head is rotated out of the material rack and moved to the support arm. One end of the support arm is connected with the support block and fixed on the frame. The other end of the support arm is connected with the first air cylinder, and the first cylinder can adjust the height of the support arm , ensure that the board material head is safely transported back into the material feeding device. The material feeding device flattens the plate material head so as to smoothly enter the leveling feeder head, and then adjusts the material blocking width of the material feeding roller and the correction amount of the leveling roller so as to ensure that the plate material is obtained reliably and effectively. level. The final plate is sent by the feeder and sent to the punch press to complete the entire automated process.