Contact: Liang Sheng

Tel: +86 (0769) 8287 2593

Mobile: +86 13712941678

Fax: +86 (0769) 8133 4403

E-mail: sanyi@dgsanyi.cn

Address: No. 2, Quanhe Street, Quantang Management District, Liaobu Town, Dongguan, China

Website: www.dgsanyi.cn

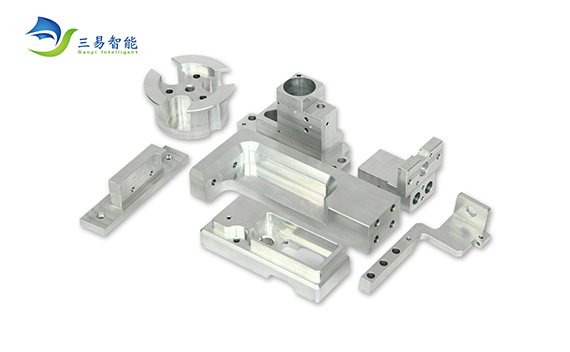

Precision parts processing has many advantages. Before that, we also shared with you the specific advantages of precision parts processing. The most obvious is that it can reach the high precision that ordinary processing can't reach, and high precision also depends on precision processing equipment and accurate The system is restrained, and precision masks are used as intermediates to achieve extremely fine control of the amount of material removed or added to the outer surface. What are the characteristics of precision parts processing? The following is a detailed introduction by our chief engineer of Sanyi Intelligence:

First, precision parts cutting

There are precision turning, mirror grinding and grinding. Fine turning lathes are machined on precision lathes using micro-cutting single-crystal diamond turning tools. The cutting thickness is only about 1 micron. It is often used to machine non-ferrous metal materials such as spherical, aspherical, and plane reflectors with high precision and appearance. . For example, an aspherical mirror with a diameter of 800 mm is used for processing nuclear fusion devices. The highest precision is 0.1 μm and the apparent roughness is Rz 0.05 μm.

Second, precision parts processing

When precision machining of precision parts is targeted at nanometers or even at the end of atomic units (atomic lattice distances of 0.1 to 0.2 nanometers), ultra-precision machining of parts can no longer be adapted, and special high-precision machining of parts is necessary, ie, application of chemical energy. Electrochemical energy, thermal energy, or electrical energy, etc., enable these energy to exceed the joint energy between atoms, thereby removing the attachment, joint, or lattice distortion between parts of the workpiece's outer surface to achieve the purpose of ultra-precision machining. Among such processes are mechanical chemical polishing, ion sputtering and ion implantation, electron beam exposure, laser beam processing, metal evaporation, and molecular beam epitaxy.

The characteristics of precision parts processing are introduced here today. For more information, please visit our news center.

Our main products include: non-standard micro components, stainless steel components, medical equipment accessories, lighting accessories, fasteners, connectors, instrumentation accessories, shaft sleeve, fiber optic connector, lc tail handle, sc tail handle, Precision machinery parts, optical fiber communication accessories, screw nuts, electronic product accessories, copper, aluminum rivets and other civilian, military high standards of high quality and high cleanliness products more than 200 varieties for customers to choose. In addition, we can also produce products that customers are satisfied with according to the different requirements of customers.