Contact: Liang Sheng

Tel: +86 (0769) 8287 2593

Mobile: +86 13712941678

Fax: +86 (0769) 8133 4403

E-mail: sanyi@dgsanyi.cn

Address: No. 2, Quanhe Street, Quantang Management District, Liaobu Town, Dongguan, China

Website: www.dgsanyi.cn

The mounting rate of the mounter directly affects the production capacity, which is related to the interests of the SMT processing manufacturers. The two components that affect the placement rate of the placement machine are the label feeder (Feida) and the suction nozzle. The following three easy-to-use smart editors explain some important factors that affect the mounting rate of the placement machine.

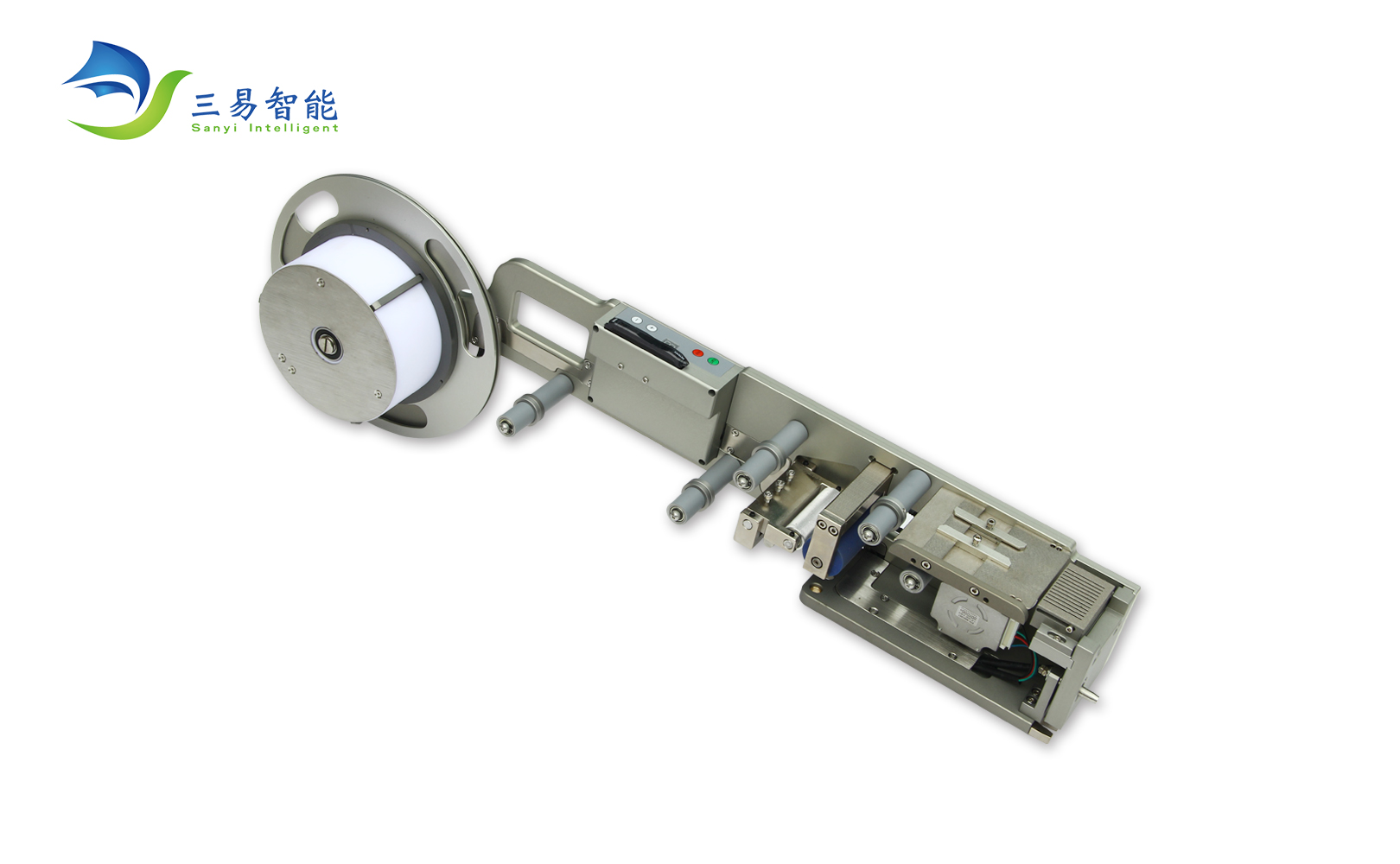

The label feeder (Feida) affects the mounter placement efficiency as long as the supply is abnormal. The drive methods of the feeder include motor drive, mechanical drive, and cylinder drive. Take the mechanical drive as an example, let's say that the feeder affects the patch. Reasons for machine placement efficiency:

The effect of the wear of the driver of the label feeder (Feida) on the mounting rate of the placement machine:

Drive mechanically by the cam spindle to drive the feeding mechanism, quickly tapping the hitter arm of the feeder, and connecting the ratchet with the ratchet wheel to drive the component tape forward one pitch, and at the same time, driving the plastic reel. The plastic cap is removed, and the nozzle is lowered to complete the take-out action. However, due to the high-speed feeder feeder feeder Feida, after a long time of use, placement machine Feida ratchet paw wear is serious, resulting in the paw can not drive the tape reel stripping normal strip, the ratchet wheel has worn The placement machine Feida should be repaired immediately, and those that cannot be repaired should be promptly replaced.

Label Feeder (Feida) Affects Some Important Factors in Mounter Mounting Rate

The Effect of Bad Lubrication of Label Feeder (Feida) on Mounting Rate of Chip Mounter

Generally, the maintenance of the placement machine feeder is easy to ignore, so that it is easy to cause the placement machine feeder often cassette, thereby affecting the mounter placement rate. However, regular cleaning, cleaning, and lubrication maintenance are essential tasks.

Effect of Structural Deformation of Label Feeder (Feida) on Mounting Rate of Chip Mounter:

Due to improper use of long-term use or operator, the placement machine Feida is deformed, rusted, etc., due to its long-term use or operator's pressure, which leads to the period of absorption, standing or insufficiency during the period, thus seriously affecting. Mounter placement rate. Therefore, regular inspections should be conducted to identify problems and deal with them in a timely manner so as to avoid excessive waste of parts. At the same time, the feeders should be installed correctly and firmly on the feeder platform, especially if there is no feeder height detection device, otherwise it may cause The feeder or mounter is damaged.

In addition to the label feeder (Feida) will affect the placement rate of the placement machine, there are many reasons, such as the suction nozzle, the motor operator error has affected the placement rate of the placement machine. Therefore, while regularly maintaining the placement machine, we must continue to provide the operator's operating skills and qualities.